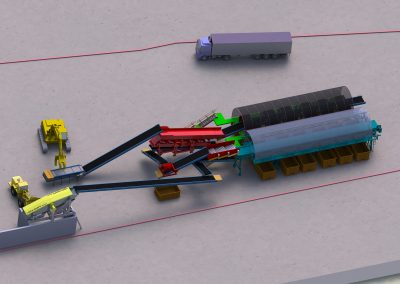

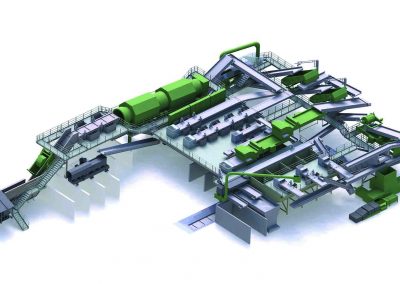

TYPICAL PROCESS LAYOUT

WEEE processing, a typical process

Automated recovery of valuable materials from used electrical goods.

CP Sizing Screen

High throughput and highly durable sizing screen, with a modular design enabling the screening area to be as long as required.Download Product PDF

High throughput and highly durable sizing screen, with a modular design enabling the screening area to be as long as required.Download Product PDF

High Capacity Air Drum

Using adjustable air direction and air velocity to separate materials by their own weight in a highly compact footprint design.

Using adjustable air direction and air velocity to separate materials by their own weight in a highly compact footprint design.

Fines Trommel

To screen the smaller particles with the screen sections being changeable depending on the output size required.

To screen the smaller particles with the screen sections being changeable depending on the output size required.

CP Screen

High throughput Screen with on-the-fly speed and angle adjustment to vary the split of 3D and 2D materials as well as a Fines removal, these units can also be fitted with different surface materials depending on the material being processed to maximise separation efficiency.

High throughput Screen with on-the-fly speed and angle adjustment to vary the split of 3D and 2D materials as well as a Fines removal, these units can also be fitted with different surface materials depending on the material being processed to maximise separation efficiency.

MSS Optical Sorters

Optical Sorting Near-Infra-Red technologies to sort and clean up material streams for separated plastic types, glass by colour, paper, cardboard, wood, metals and WEEE. MSS optical sorters can provide up to 5 outputs from a single unit when utilising the Twin eject and Dual pass systems.Download Product PDF

Optical Sorting Near-Infra-Red technologies to sort and clean up material streams for separated plastic types, glass by colour, paper, cardboard, wood, metals and WEEE. MSS optical sorters can provide up to 5 outputs from a single unit when utilising the Twin eject and Dual pass systems.Download Product PDF